Lasdrop Marine Shaft Seals

Clean. Dry. Reliable.

Both mechanical face seals, and lip seal options available, suitable for both recreational leisure craft and commercial vessels.

45 plus years of experience, Lasdrop offer the highest quality shaft seals on the market. Available in both metric and imperial sizing up to 6 Inch as standard, with bespoke solutions available on request.

Mechanical Shaft Seals

The Generation 2 shaft seal incorporates a unique ball-bearing drive system that allows the seal ring to “float” and remain in constant contact with the carbon graphite seal surface, ensuring the seal is watertight.

Pressure Housing -vs- Bellows Hose. The Gen2 shaft seal creates compression via an innovative pressure housing, eliminating the need for a bellows hose. This pressure housing is far longer lasting when compared to a bellows design, resulting in less maintenance over the life of the seal.

Integrated Bearing Design. An integrated water lubricated bearing allows the seal body to follow the shaft ensuring proper face seal alignment. Note: ALL Lasdrop bearing housings have tolerances within 0.001. The integrated bearing allows the seal body to self-align following the shaft.

Integrated Clamping System. The Gen2 pressure housing secures to the shaft through a simple integrated clamping system. This eliminates the need for set screws – which can lead to damage of the shaft & slippage after their first use leading to a less secure and stable seal.

Sizing. Shaft seal Diameter from 1” to 5” (25mm to 100mm), Stern tube 1 3/4“ to 8” (45mm to 178mm). Bespoke sizes available on request.

Key Features

- The Gen II uses a 316-marine grade stainless steel spring to provide pressure to the seal surfaces. Together, the spring and seal ring rotate along with the shaft and remain secured in the Clamp/Pressure housing.

- The Clamp/Pressure housing is secured to the shaft without the use of set screws preventing galling or damage to the shaft.

- Dual u-cup seals, which also rotate on the shaft, are seated inside of the seal ring, and prevent the passage of water to this point.

- The friction ring assembly is constructed from a durable copolymer housing protecting the carbon graphite friction ring and incorporates a water lubricated bearing maintaining correct alignment to the shaft.

- Each kit includes AWAB hose clamps that are manufactured from 316 stainless steel with rolled band edges to eliminate risk of damage to the hose. The non-perforated band provides twice the tensile strength of a regular clamp.

- All units have dual water injection ports including necessary hardware.

Click Image to Open in Lightbox

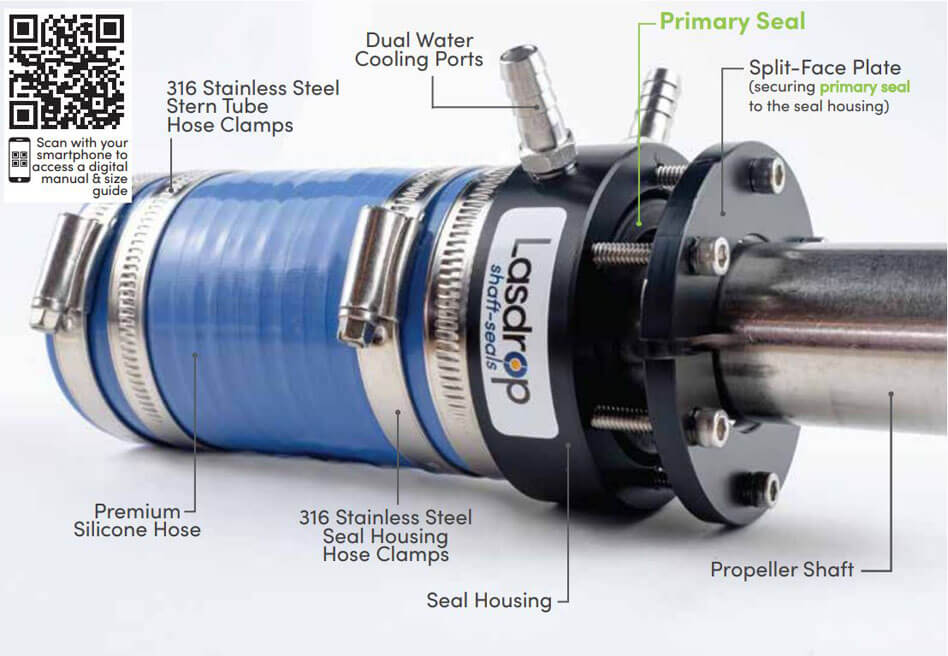

Lip Seal Shaft Seals

Two lip seal shaft seal options are available, Lasdrop DrySeal & Lasdrop EliteSeal. Both variants us a Nitrile lip seal, made specifically for marine use, it is in constant low friction contact with the propeller shaft, preventing water from passing into your vessel. Both models incorporatee a water lubricated alignment bearing in the housing to keep the unit properly aligned with the shaft.

Both options have a unique split face plate design enabling the lip seal to be changed without the need to remove the shaft or entire unit, reducing maintenance time and costs when seals need replacement.

The Lasdrop EliteSeal has an additional compartment that is secured to the housing that can hold two spare lipseals (1 spare comes with the shaft seal) safeguarding them from damage.

Sizing. Shaft seal Diameter from 3/4” to 6” (20mm to 145mm), Stern tube 1 3/4“ to 10” (38mm to 203mm). Bespoke sizes available on request.

Key Features

- A split-face plate makes it easy to replace the inner lip seal without the need for special installation tools.

- An optional back-up seal can rotate freely on the shaft until replacement is needed.

- The seal housing is constructed from durable copolymer with built in water lubricated bearing, insuring proper alignment to the shaft.

- Each kit includes AWAB hose clamps that are constructed of 316 stainless steel with rolled band edges to eliminate risk of damage to the hose. The non-perforated band provides twice the tensile strength of a regular clamp.

- All units have dual water injection ports including necessary hardware.

- EliteSeal has Seal case encompassing a back-up seal that rotates freely on the shaft until replacement is needed.

EliteSeal

Click Image to Open in Lightbox